In the world of metal fabrication, the role of an effective Aluminum Welder cannot be overstated. As the industry continues to evolve, the demand for reliable and precise welding equipment has skyrocketed. Renowned welding expert, John Smith, once remarked, "The quality of welds we produce not only affects structural integrity but also impacts the overall aesthetics of any project." This statement underscores the critical importance of selecting the right welder for aluminum, a material known for its lightweight and versatility but also its unique challenges during the welding process.

In 2023, professional welders face an impressive array of technology designed for optimal performance. With advancements in design and functionality, choosing the best aluminum welders has become essential for achieving professional quality results. From the intricacies of TIG welding to the robustness needed for MIG welding, the right aluminum welder can significantly enhance a craftsman’s ability to execute precision work that stands the test of time. In this guide, we will explore the ten best aluminum welders available this year, emphasizing their features and benefits to help you make an informed decision for your welding projects.

When selecting an aluminum welder, it is essential to consider the type of welding processes it supports. Aluminum welding typically requires techniques such as TIG or MIG, with each method offering unique advantages. For instance, TIG welding provides greater control and precision, making it ideal for thin materials or detailed projects, while MIG welding is often faster and better suited for larger workpieces. Understanding the specific requirements of your project will guide your choice in selecting a welder that excels in the desired welding method.

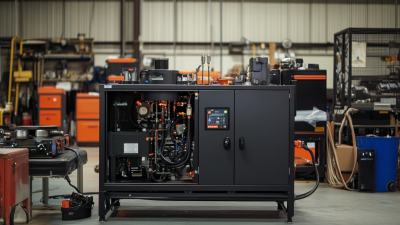

Another critical factor is the welder's power output and duty cycle. A welder with a higher amperage range can handle thicker materials more efficiently, while the duty cycle—essentially the welder’s operating time before it needs to cool down—determines how long continuous welding can be performed. For professional projects that involve extensive welding, a welder with a higher duty cycle ensures reliability and minimizes downtime.

Additionally, features such as adjustable settings, portability, and ease of use play a significant role in enhancing the overall welding experience and achieving professional-quality results.

When selecting the best aluminum welders, professional quality and precision are paramount. Aluminum is known for its light weight and excellent strength-to-weight ratio, making it a popular material in various industries, including automotive and aerospace. To achieve optimal results, welders need equipment that offers precision and control over the welding process. Factors such as the welder's power output, heat control capabilities, and duty cycle play crucial roles in determining the performance of these machines during work.

A comprehensive comparison of top aluminum welders involves evaluating their features, capabilities, and ease of use. For instance, some welders are designed for both MIG and TIG welding processes, allowing for versatility in handling different aluminum alloy compositions. Additionally, the presence of advanced technology such as digital displays and automatic settings can significantly enhance the welding experience, providing users with real-time feedback and adjustments. Ultimately, identifying a welder that combines durability with precision ensures that professionals can deliver high-quality results consistently, meeting the demanding requirements of their projects.

When selecting the best aluminum welders for professional-grade projects, understanding the features and specifications is essential. One critical aspect to consider is the welder's output capabilities. Ideally, professional aluminum welders will offer a wide range of amperage settings, allowing users to adjust the heat according to the thickness of the material. Additionally, a welder with a stable arc and minimal spatter will yield cleaner welds, enhancing both the precision and appearance of the finished work.

Another important feature is the welding process compatibility. Most high-quality aluminum welders are designed to support both TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding techniques, offering versatility for different projects. The inclusion of adjustable controls for features like voltage and wire feed speed can also greatly influence ease of use and the quality of the weld. Furthermore, an efficient cooling system is crucial to prevent overheating during extended use, ensuring reliability in demanding environments. Ultimately, these specifications play a vital role in determining the overall performance and durability of aluminum welders tailored for precision work.

When it comes to maintaining an aluminum welder, regular care can significantly extend its life and ensure it delivers consistent performance. One of the most important practices is to keep the equipment clean. After each use, it's essential to remove any spatter, dust, or residue that may have accumulated. This not only helps in maintaining the welder’s efficiency but also prevents potential damage to internal components. A thorough inspection of cables, connectors, and hoses should be conducted regularly to identify any wear or heat damage that could lead to operational issues.

In addition to cleaning, proper storage plays a crucial role in prolonging the lifespan of an aluminum welder. It is advisable to store the equipment in a dry and cool environment, away from direct sunlight. Using protective covers can also help shield the welder from dust and debris when not in use.

Moreover, regularly checking and replacing consumable items such as nozzles and contact tips is vital, as worn components can compromise weld quality and increase unnecessary wear on the device. Adopting these maintenance tips can ensure that your aluminum welder remains in top condition, ready to tackle precision work whenever needed.

When selecting the best aluminum welders for professional applications in 2023, user reviews and ratings play a crucial role in guiding prospective buyers. Enthusiasts and professionals alike have shared their experiences with various models, highlighting key features such as ease of use, portability, and versatility. Many users emphasize the importance of a welder's duty cycle and heat settings, noting that these factors significantly impact performance when working with aluminum materials. This feedback often drives potential buyers to prioritize models that have garnered high praise for their reliability and precision.

Moreover, safety features and customer support are common themes in user comments. Many welders stress the value of a welder that not only performs well but also includes safeguards to protect users during operation. These insights shed light on the aspects that matter most to professionals, helping them to make informed choices. With a plethora of options on the market, reviewing firsthand accounts and star ratings can reveal which aluminum welders live up to their promises and deliver the professional quality needed for intricate tasks.

This chart displays user ratings for the best aluminum welders based on reviews and ratings in 2023. Each model is rated on a scale of 1 to 5.