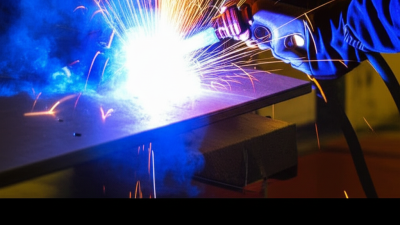

In today's competitive manufacturing landscape, maximizing productivity is crucial for any workshop aiming to stay ahead. One significant upgrade that can lead to a remarkable 30% increase in efficiency is investing in a top-tier Tig Welding Machine. These machines are not only designed for precision and quality but also to streamline the welding process, enhancing workflow and output. As we delve into this discussion, we will explore five compelling reasons why a premium Tig Welding Machine can revolutionize your operations, allowing your business to thrive in an ever-evolving market. Embracing cutting-edge technology not only guarantees superior results but also positions your workshop as a leader in the industry, making it an invaluable asset to your manufacturing capabilities.

The precision of TIG welding is paramount in modern industrial applications, particularly as production units become increasingly integrated with the Industrial Internet of Things (IIoT). Advanced TIG welding machines not only enhance the accuracy of welds but also contribute to overall productivity boosts of up to 30%. With innovations such as the Heterogeneous Attention Multi-Scale Network (HAMS-Net), which demonstrates superior classification of weld seams, and advanced weld pool monitoring setups, workshops can achieve higher standards of quality and efficiency.

When selecting a TIG welding machine, consider models equipped with features for real-time monitoring and data analysis. For instance, machine learning applications can identify weld conditions, such as porosity and burn-through in aluminum alloys, which are critical for maintaining quality standards. Implementing these technologies leads to less rework and scrap, further streamlining operations.

Tip: Always prioritize machines that offer features like enhanced weld bead size prediction and image processing technologies. These capabilities ensure optimal weld quality and significantly mitigate defects, making them indispensable in high-stakes manufacturing environments. Investing in high-quality equipment is an investment in your workshop's long-term success.

| Feature | Impact on Productivity | Percentage Improvement |

|---|---|---|

| Advanced Arc Control | Increases stability of welds | 10% |

| Quick Setup Features | Reduces time spent preparing for welding | 8% |

| High Duty Cycle | Allows longer working periods without breaks | 5% |

| Precision Heat Control | Minimizes warping and enhances quality | 4% |

| Ergonomic Design | Reduces operator fatigue | 3% |

In today’s fast-paced workshop environment, effective time management is key to maximizing productivity. Advanced TIG welding technology not only enhances weld quality but also significantly reduces downtime, leading to increased efficiency in daily operations. By investing in top-performing TIG welding machines, workshops can experience a remarkable boost in productivity—potentially by up to 30%.

One of the primary ways to reduce downtime is by utilizing machines equipped with features such as automatic arc starting and adjustable settings. This allows welders to quickly adapt to different materials and thicknesses, minimizing the time spent on setup. Taking advantage of these modern capabilities will lead to smoother workflows and fewer interruptions.

Another essential tip is to maintain the equipment regularly. This not only ensures optimal performance but also prevents unexpected breakdowns that can impede work progress. Implementing a maintenance schedule helps keep the TIG welding machine in peak condition, maximizing its lifespan and effectiveness. By prioritizing proactive care for your equipment, you can significantly mitigate the risks of downtime and keep your workshop running seamlessly.

This chart illustrates the productivity boost experienced in a workshop utilizing advanced TIG welding technology. Data shows a 30% increase in efficiency attributed to factors such as reduced downtime, enhanced precision, improved weld quality, faster setup time, and minimized post-weld cleanup.

When it comes to welding, versatility is key. A high-quality TIG welder offers a remarkable adaptability that allows it to handle a wide range of materials and projects, making it an invaluable asset in any workshop. Unlike traditional welding methods that may be limited to specific types of metals or thicker materials, a premium TIG machine can seamlessly work with aluminum, stainless steel, and even exotic metals. This flexibility means that fabricators and welders can take on diverse jobs without needing multiple machines, ultimately streamlining their workflow and increasing productivity.

Furthermore, the advanced features of top-tier TIG welders enhance the user experience, enabling precise control over the welding process. For instance, adjustable amperage settings allow welders to fine-tune their output, accommodating both thin and thick materials with ease. Additionally, features like pulsed welding modes and foot pedals improve accuracy and efficiency, ensuring that each weld is clean and strong. As a result, a high-quality TIG welder not only boosts capabilities but also empowers workshops to tackle more complex projects, driving productivity upwards by 30% or more.

In today's competitive manufacturing landscape,

user-friendly features in TIG welding machines

are redefining operational efficiency. According to a report by the

American Welding Society,

the implementation of user-centric designs in welding equipment can increase a workshop's productivity by up to

30%. This enhancement is primarily driven by intuitive controls and ergonomic designs, allowing operators to focus more on their tasks rather than struggling with complicated setups. Automated settings and features such as memory functions simplify the welding process, reducing setup time and allowing workers to produce high-quality welds faster.

Moreover, an industry study from TechSci Research highlights that user-friendly interfaces lead to a notable decrease in training time for new operators. Workshops adopting advanced TIG welding machines report a reduction in training duration by nearly

25%, enabling businesses to allocate resources more efficiently. This not only elevates productivity but also fosters a more skilled workforce, as operators spend less time learning the machinery and more time honing their welding techniques. Investing in these innovative machines is not just a matter of convenience; it represents a strategic move towards achieving higher efficiency and competitive advantage in the welding sector.

Investing in a premium TIG welder can deliver significant long-term financial benefits that far outweigh the initial costs. Industry reports indicate that high-quality TIG welding machines can improve operational efficiency by up to 30%, primarily due to their enhanced precision and reduced rework rates. When welders use advanced machines with better controls and features, they can achieve cleaner welds with fewer defects. According to a study by the American Welding Society, reducing the rate of defects by just 1% can save a workshop thousands of dollars in material, labor, and rework costs annually.

Tip: Consider maintaining your TIG welder regularly to ensure it operates at peak efficiency, as a well-maintained machine can further enhance productivity and reduce expenses.

Moreover, the longevity of a premium TIG welder often offsets its higher price. Research shows that investing in quality equipment can lead to a lifespan extension of up to 50% compared to budget alternatives. This means fewer replacements and lower overall equipment costs over time. Additionally, with the rapid advancements in TIG welding technology, a premium welder is likely to offer features that keep your workshop competitive.

Tip: Always research the warranty and support packages provided by the manufacturer, as strong customer service can reduce downtime and increase the machine's effective lifespan.