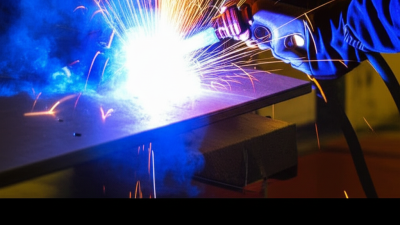

Electric welding is an essential skill in the manufacturing and construction industries, and mastering its techniques can significantly enhance one's career prospects. According to a report by the American Welding Society, the welding industry is projected to grow 26% by 2028, highlighting the increasing demand for skilled welders. Additionally, the National Center for Construction Education and Research emphasizes that proper electric welding techniques can reduce errors by up to 30%, thereby increasing productivity and safety on job sites. For beginners looking to advance their skills, understanding the fundamentals of electric welding is crucial, not only for personal development but also for meeting the industry's evolving standards. This article offers essential tips that will help novice welders refine their techniques and build a solid foundation for their future careers in electric welding.

Electric welding is a crucial skill in various industries, and understanding the basics is essential for any beginner looking to advance their abilities. The foundation of successful electric welding starts with the right tools and equipment. Essential items include a reliable welding machine, protective gear such as gloves and helmets, and the appropriate electrodes or filler materials. According to a report by the American Welding Society, nearly 50% of welding novices list lack of equipment knowledge as their primary hurdle, highlighting the significance of familiarizing oneself with the tools of the trade.

Moreover, selecting the correct welding machine is imperative. Among the various types available, MIG (Metal Inert Gas) welding is often recommended for beginners due to its versatility and ease of use. A study conducted by the Welding Institute indicates that MIG welding accounts for over 30% of welding applications across industries, demonstrating its widespread adoption and reliability. Additionally, investing in high-quality safety gear cannot be overstated, as the National Institute for Occupational Safety and Health reports that almost half of all welding injuries are related to inadequate protective equipment. By understanding and acquiring these essential tools, aspiring welders can set a solid groundwork for mastering electric welding techniques.

When diving into electric welding, safety should always be a top priority. Whether you're a novice or looking to enhance your welding skills, adhering to key safety practices can help ensure a secure working environment. Essential safety gears, such as helmets, gloves, and protective clothing, are crucial to shield against harmful sparks and intense heat. Additionally, understanding the materials you are working with can prevent hazardous situations from arising.

Moreover, staying compliant with safety regulations, similar to those enforced by maritime authorities, is vital in welding environments. Make sure to familiarize yourself with updated guidelines that govern your work area. Always ensure ventilation is adequate to prevent the buildup of harmful fumes and gases.

Tips for beginners: Always inspect your equipment before use to avoid potential malfunctions, and never work alone in confined spaces without proper planning and rescue protocols in place. Regularly engage in safety training to keep your knowledge up-to-date. By cultivating these practices, you not only protect yourself but also contribute to a safer workplace for everyone involved.

| Technique | Description | Safety Practices | Recommended Gear |

|---|---|---|---|

| MIG Welding | Uses a continuous wire feed as an electrode. | Wear a welding helmet and gloves; ensure proper ventilation. | Welding helmet, gloves, fire-resistant jacket. |

| TIG Welding | Involves a non-consumable tungsten electrode. | Use a suitable shield; maintain a clean work area. | TIG torch, welding gloves, high-quality helmet. |

| Stick Welding | Utilizes a consumable electrode coated in flux. | Check for gas leaks and avoid flammable materials. | Electrode holder, safety goggles, insulated gloves. |

| Flux-Cored Welding | Uses a tubular wire filled with flux for shielding. | Keep a fire extinguisher nearby, and wear protective clothing. | Welding jacket, gloves, respiratory protection. |

When exploring the world of electric welding, understanding the various techniques is essential for beginners aiming to refine their skills. Five common welding techniques—MIG, TIG, Stick, Flux-Cored, and Submerged Arc welding—each offer unique benefits and applications based on the materials and environments involved. For example, MIG welding is favored for its speed and versatility, making it suitable for both thin and thick materials. Reports indicate that MIG welding accounts for about 32% of all industrial welding processes, highlighting its popularity among professionals.

To master these techniques, beginners should focus on their specific applications. For instance, TIG welding delivers high precision and is ideal for thin metals, especially in industries like aerospace, where weld integrity is paramount. On the other hand, Stick welding is valued for its adaptability in outdoor conditions and can be used on rusty or dirty metals, making it a go-to for construction projects.

**Tip:** Always start with the right settings on your welding machine; improper voltage can lead to poor penetration or burn-through. **Tip:** Practice on scrap materials to gain confidence in your technique before tackling actual projects. Each technique has its learning curve and mastering them will be beneficial for your welding journey.

When it comes to mastering electric welding techniques, understanding welding positions and movements is crucial for beginners aiming to elevate their skills. According to the American Welding Society (AWS), nearly 60% of welding defects are attributed to improper technique, emphasizing the need for attention to positional accuracy. Common welding positions include flat, horizontal, vertical, and overhead, each requiring distinct techniques and body movements to ensure proper penetration and bead appearance. For instance, in the overhead position, welders must maintain a steady hand while directing the arc, which can lead to fatigue and increased error if not practiced regularly.

Adopting correct movements while welding can dramatically influence the quality of the work produced. The National Institute for Occupational Safety and Health (NIOSH) reports that welders often face musculoskeletal injuries due to poor posture and repetitive strain from awkward positions. To mitigate these risks, beginners should focus on maintaining ergonomic body alignment and use tools that provide better reach and control. Regular drills and practice sessions can help reinforce these skills, ensuring that welders develop muscle memory for precise and fluid movements. Mastering these fundamental techniques will not only enhance the quality of the welds but also contribute to a safer work environment.

Welding is a skill that requires precision and practice, and beginners often face challenges that can hinder their progress. Common issues such as poor arc stability, inconsistent bead appearance, and machine settings can be frustrating. According to a report by the American Welding Society, nearly 30% of novice welders experience difficulties with maintaining a steady arc, which is crucial for quality welds. Understanding how to troubleshoot these problems is key to improving welding techniques.

One essential tip for overcoming welding challenges is to ensure proper equipment setup. For instance, adjusting the amperage according to material thickness can significantly impact the quality of your welds. A general rule of thumb is to set the amperage to 1 amp per 1/1000 inch of material thickness. Additionally, always check your electrode angle; a 15-degree angle can enhance arc control and shorten the arc length for better penetration.

Another frequent issue is contamination of the welding surface. It is critical to clean the area thoroughly to remove rust, paint, or oil, as these contaminants can lead to weak welds. A simple method is to use a wire brush or grinder before welding. Following these tips will help beginners not only resolve existing problems but also build a solid foundation for advancing their skills in electric welding.