When embarking on a welding project, selecting the appropriate welder equipment is crucial for achieving successful results. The vast array of options available can be overwhelming, but understanding your specific needs and the nuances of different types of welding machines can simplify the decision-making process. This guide aims to provide valuable insights and tips on how to navigate this landscape effectively.

Choosing the right welder equipment involves considering various factors, including the type of materials you will be working with, the nature of your projects, and your skill level. Whether you are a hobbyist, a professional, or someone in between, having a clear idea of your requirements will help you make an informed choice. This introduction serves as a foundation for discussing the essential criteria and features to evaluate when selecting welder equipment, ensuring that you are well-prepared to tackle your welding endeavors with confidence.

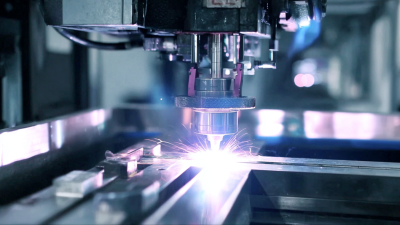

When selecting the right welding equipment, it’s crucial to understand the various types available in the market, each suited for different applications and materials. According to the American Welding Society (AWS), the most common forms of welding include MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welding. MIG welding, known for its versatility and speed, is ideal for beginners and is often used in structural and fabrication industries. TIG welding, while more complex, provides superior precision, making it perfect for thin materials like stainless steel and aluminum. Stick welding, while it offers portability and ease of use, is primarily used in outdoor conditions where wind can affect other welding processes.

The global welding equipment market is projected to reach USD 25 billion by 2025, as reported by Mordor Intelligence. This growth reflects the increased demand across various industries such as construction, automotive, and aerospace, which in turn influences the variety of equipment available. Advanced technologies like robotic welding and automated systems are becoming increasingly prevalent, enhancing productivity and safety in welding operations. Understanding these types and the market trends can help you make an informed decision when choosing equipment that aligns with your project requirements and future needs.

When selecting the right welder equipment for your projects, there are several key factors to consider that can significantly impact your welding experience and outcome. First and foremost, understanding the type of welding process you plan to use is essential. Different welding techniques such as MIG, TIG, and stick welding require specific equipment tailored to their unique operational needs. For instance, if you need to weld thin materials, a MIG welder could be more suitable due to its ease of use and efficiency for such tasks.

Another vital aspect is the power source available for your welding setup. Electric welders are the most common, but you may also consider gas-powered options depending on your work environment and the nature of your projects. Additionally, factors like the thickness of the materials you’ll be working with, the type of metal involved, and the frequency of use all play significant roles in determining the right welder for your needs. Always ensure that the equipment's duty cycle aligns with your workload requirements, as this influences the welder's ability to perform consistently without overheating during extended periods of use.

When selecting the appropriate welding equipment for your projects, understanding the technical specifications of welding machines is crucial. Key factors to evaluate include the type of welding process (MIG, TIG, or Stick), amperage range, duty cycle, and voltage requirements. According to the American Welding Society (AWS), the duty cycle of a welding machine indicates how long it can operate at a specified amperage within a 10-minute period without overheating. For example, a machine with a 60% duty cycle at 200 amps can run continuously for 6 minutes and must cool down for 4 minutes. This specification is vital for ensuring the welder can handle your workload efficiently.

Furthermore, the amperage range directly influences the thickness of materials you can weld. Research published by the Welding Equipment Manufacturers Association (WEMA) highlights that a welder with a minimum output of 30 amps is suitable for thin materials, while those needing to join thicker materials may require machines capable of delivering upwards of 300 amps. Additionally, voltage requirements should align with the available power supply in your workshop; keep in mind that higher voltage can provide deeper penetration and faster travel speeds, essential for certain applications. By carefully considering these technical specifications, you can choose a welding machine that meets the demands of your specific projects while optimizing productivity and ensuring safety.

When selecting welding equipment, prioritizing safety features is essential to ensure both the welder’s protection and the integrity of the project. A good welding helmet equipped with an auto-darkening feature is crucial, as it allows for improved visibility during preparation and offers immediate shading during the welding process. Additionally, look for helmets that provide a high level of ultraviolet and infrared protection, which is vital in guarding against harmful radiation that can cause skin or eye damage.

Another important aspect of safety is the use of appropriate protective gear and accessories. Heavy-duty welding gloves should be selected to offer protection from heat and sparks while maintaining dexterity. A flame-resistant welding jacket is also highly recommended, as it protects your skin from spatter and extreme heat. Moreover, consider using a welding apron and a set of safety glasses to further shield yourself from the potential hazards associated with welding. Incorporating these safety features and accessories will not only enhance your personal safety but also contribute to a more efficient and successful welding experience.

| Welding Process | Safety Features | Recommended Accessories | Ideal Projects |

|---|---|---|---|

| MIG Welding | Automatic shut-off, gas leak detection | Welders gloves, welding mask | Automotive repair, light fabrication |

| TIG Welding | High-frequency start, pedal control | Fume extractor, tungsten holders | Aerospace, thin metal fabrication |

| Stick Welding | Overload protection, insulated cables | Chipping hammer, wire brush | Heavy-duty welding, construction |

| Flux-Cored Welding | Spatter reduction feature, ventilation system | Welding apron, protective boots | Outdoor fabrication, shipbuilding |

| Plasma Cutting | Arc stability control, thermal overload protection | Cutting goggles, heavy-duty gloves | Metal art, sheet metal work |

When it comes to selecting welder equipment, one of the most critical factors to consider is budgeting, which encompasses both cost and value. According to a 2021 report by the American Welding Society, choosing the right equipment can significantly impact not only project costs but also long-term productivity and operational efficiency. A well-planned investment in welding equipment can enhance the quality of work produced, ultimately leading to fewer defects and rework, which are costly in both time and resources.

For projects where precision and reliability are paramount, it is often advisable to invest a bit more upfront. Data from industry analyses indicate that high-quality units can yield a return on investment (ROI) of up to 35% over their lifespan compared to cheaper alternatives that may require more frequent replacements or repairs. In fact, spending an extra 20% on a reliable welder can often result in savings on consumables and maintenance over time—translating to both improved efficiency and reduced overall expenditure. Therefore, it's essential to carefully assess the balance between budget constraints and the long-term value that quality equipment provides, enabling projects to be completed efficiently without compromising standards.